FIXAR: new automated composites repair project

09 Oct 2019

A Dutch consortium initiated by Inholland Composites is joining forces to develop knowledge and technology for sustainable composites repair.

Lightweight composites are the materials of choice for high-tech, durable, corrosion- resistant complex structures. Because of their high performance-to-weight-ratio, they are extensively used as enablers for the energy transition. As a good example, composites, even though they are often regarded as “new” materials, have become mainstream in the windenergy industry since the 1980s.

“Airlines are currently replacing their existing fleets with new airplanes like the B787 and the A350 using more than 50% weight in composites. What if they get struck by lightning or a bird, break down and need repair? The MRO industry for composites applications is ramping up, but are they fast enough and do they benefit from the latest technologies? It’s time to stop wondering and start researching new ways of repair of damaged composites.”

Antoine Gerritse (Manager of Aeronautical & Precision Engineering at Inholland)

How can the aviation- and windenergy sector make composites repair economically viable by applying automated technologies? To answer this question, Inholland Composites, part of Inholland University of Applied Sciences, initiated a consortium with Dutch aviation- and wind energy SMEs, CompositesNL, and the Saxion and Amsterdam Universities of Applied Sciences. Starting in October 2019, they will embark on a 2-year applied research project FIXAR: Future Improvements for Composites Sustainable Automated Repair.

Driven by a SiA Raak MKB grant, the research question is co-developed with Dutch windenergy- and aerospace companies SPECTO Aerospace, Fusion Engineering, KVE Composites, Colosso Engineering, Pontis Engineering, Schatmaker and Carbon Racing. These SMEs have signed up for project FIXAR as their interest has a close link to their businesses.

To ensure knowledge dissemination within the Dutch Wind- and Aviation industry an advisory board has been established consisting of the Royal Netherlands Air Force, the KLM, Fokker GKN, the NLR, the TU Delft, Field lab Zephyros, the Hanze University of Applied Sciences and LM Windpower.

Combining windenergy and aerospace expertise to provide break trough opportunities for innovation.

Both windenergy- and aerospace industry rely on lightweight structures using fibre reinforced polymers and have a significantly growing installed base around the world. Both industries share similar needs, but differ in maintenance requirements, processes and maturity stages. By combining forces, this consortium is looking for ways to share and simplify knowledge on composites repair to aim for innovations using automated solutions to break through the current state of the art, often locked in the certified procedures owned by the OEM’s.

Four work packages will support answering the main research question and provide focus for the envisioned improvements for composites sustainable repairs:

- workpackage 1: benefits in automated repair solutions for (offshore) windfarms

- workpackage 2: repairability using thermoplastics

- workpackage 3: sustainable composites repair for aerospace

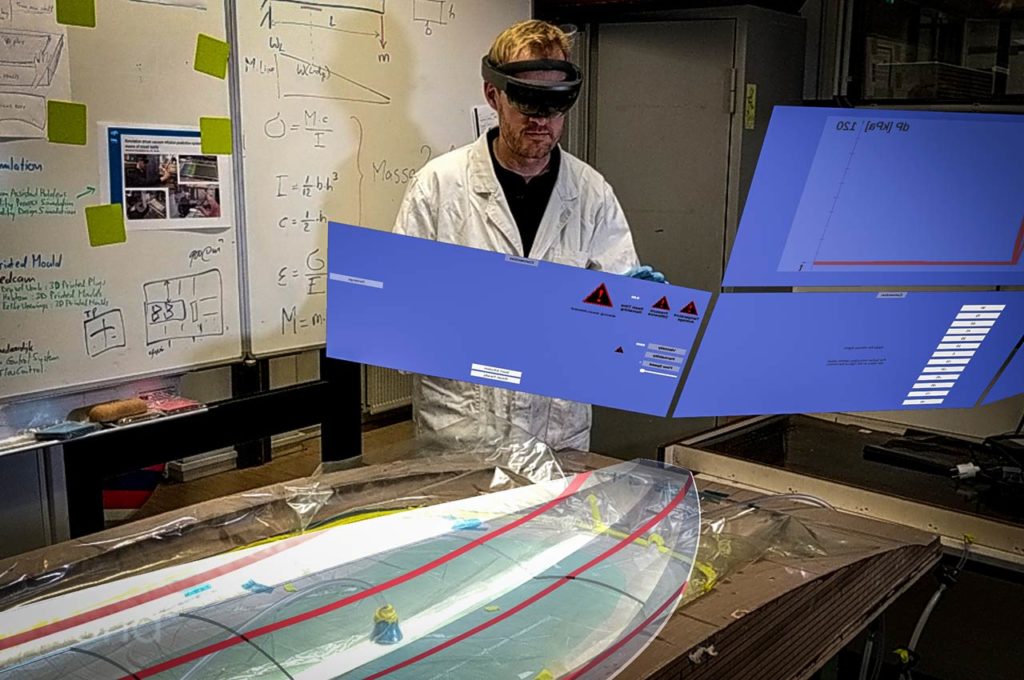

- workpackage 4: Mixed Reality for inspection and validation of repaired composites

(ref: Inholland Composites).

New technologies allow for disruptive changes in the total value chain for composites repair.

In the last few years other research programs in Europe have initiated similar projects where applying new technologies lead to significant improvements for composites manufacturing. Robotization seems the way forward for production of aircraft parts, but for the repair market these new technologies are slower in adoption. Project FIXAR is aiming to change the existing mind-set for composites repair and will collaborate with other research initiatives to drive for innovative solutions.

Fieldlab Zephyros (World Class Maintenance) recently started an innovation project AIRTuB which will focus on developing an autonomous UAV for inspection and in a later phase, also repair for wind turbines.

“Combining the themes of ‘automation’ and ‘repair’ makes a lot of sense to us, as accuracy and traceability of many parts of the repair process will benefit from using smart technologies. We also think that (semi)autonomous and automated repair solutions can significantly improve availability of wind turbines and aircraft – we believe that FIXAR can make a strong business case in certain applications. By working together with partners such as Fieldlab Zephyros we hope to leverage our knowledge base significantly and use both of our networks to increase our innovative strength for the windenergy related research”.

Rogier Nijssen (Professor in Applied Sciences in composites at Inholland)

There are plans to further expand the consortium with SME’s and fieldlabs. FIXAR is aiming to provide the following results

- State of the art on composites repair for wind energy- and aviation industry;

- Visibility of main bottlenecks for repair;

- Identification of main repair cases suitable for automation;

- Proof-of-concepts for crawler robots capable of automated inspection and repair of moving wings, rotors and wind turbine blades;

- Repair methodologies for repairing thermoplastics including validation of repaired samples;

- Innovative approaches for NDT inspections;

- Automation of analysing test results;

- Instructables on composites repair processes;

- Updates of various curricula with composites, lightweight structures, automation.

Signification research contributions are expected from lecturers, researchers and students from the involved Universities of Applied Sciences. With the consortium configuration consisting of valuable SME’s, research institutes and fieldlabs, the consortium is looking forward to the next steps.

“it is a great opportunity to increase our footprint in the Dutch wind- and aerospace sector where we are expecting to build on earlier research activities where robotic tooling and augmented reality have been used in the process of composites manufacturing.”

Arnold Koetje (Manager Project FIXAR)

(ref: Inholland Composites).

Project FIXAR will kick-off in Lelystad early November and will publish regular updates on http://projectfixar.nl. For more information you can contact arnold.koetje@inholland.nl

Leave a Reply