Automation in composites manufacturing is essential to the future growth of the composites industry. Smart manufacturing is the way to larger production volumes, lower costs, higher product quality, better employee safety and health conditions. At Inholland composites, we believe that automated manufacturing can be the key in improving product quality and worker’s environment while providing a better basis for competition in the world-wide composites industry.

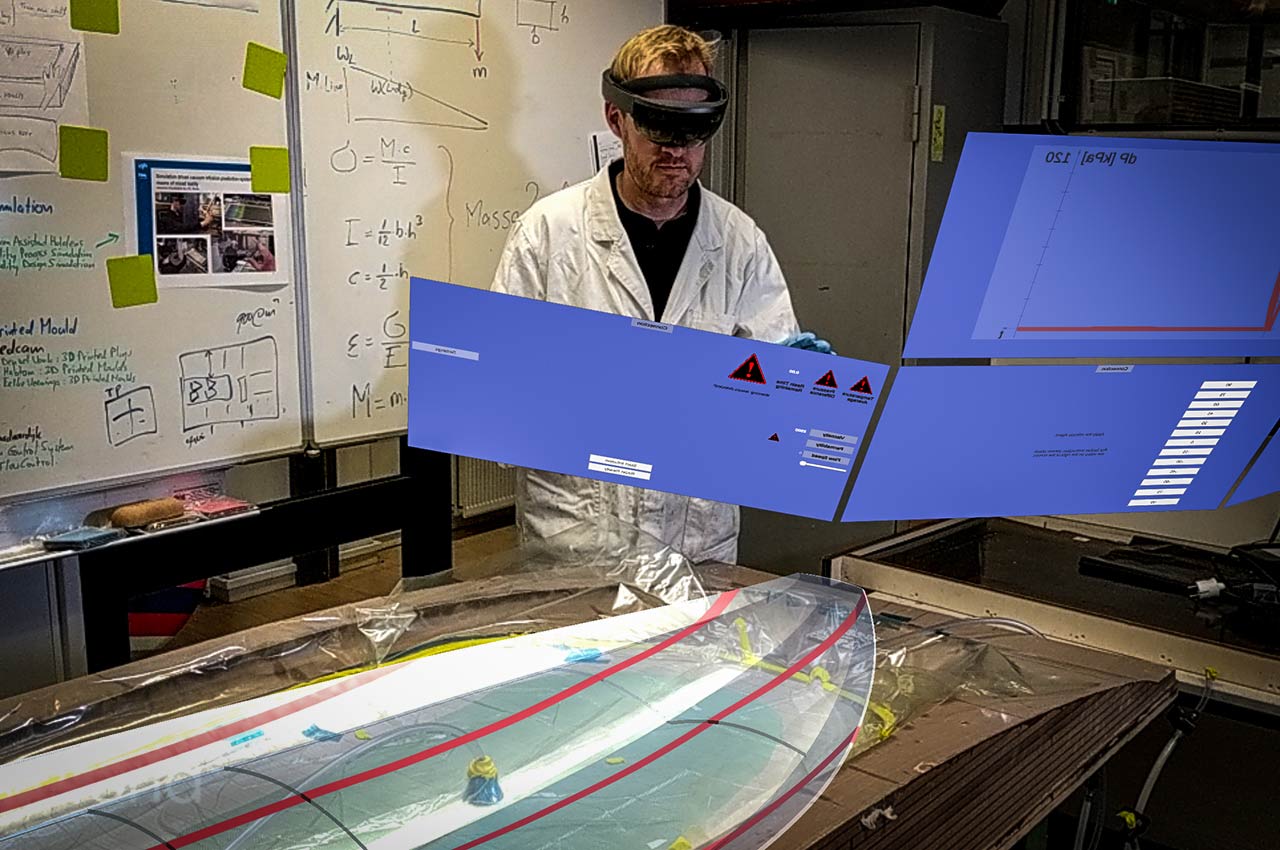

Inholland Composites therefore collaborates with the various technical departments in our University of Applied Sciences and small and medium-sized enterprises in the Netherlands to jointly develop solutions for automated composites production. Inholland Composites is currently heading a consortium with participants from the maritime industry where automation of the vacuum infusion process should lead to First-Time-Right Production.

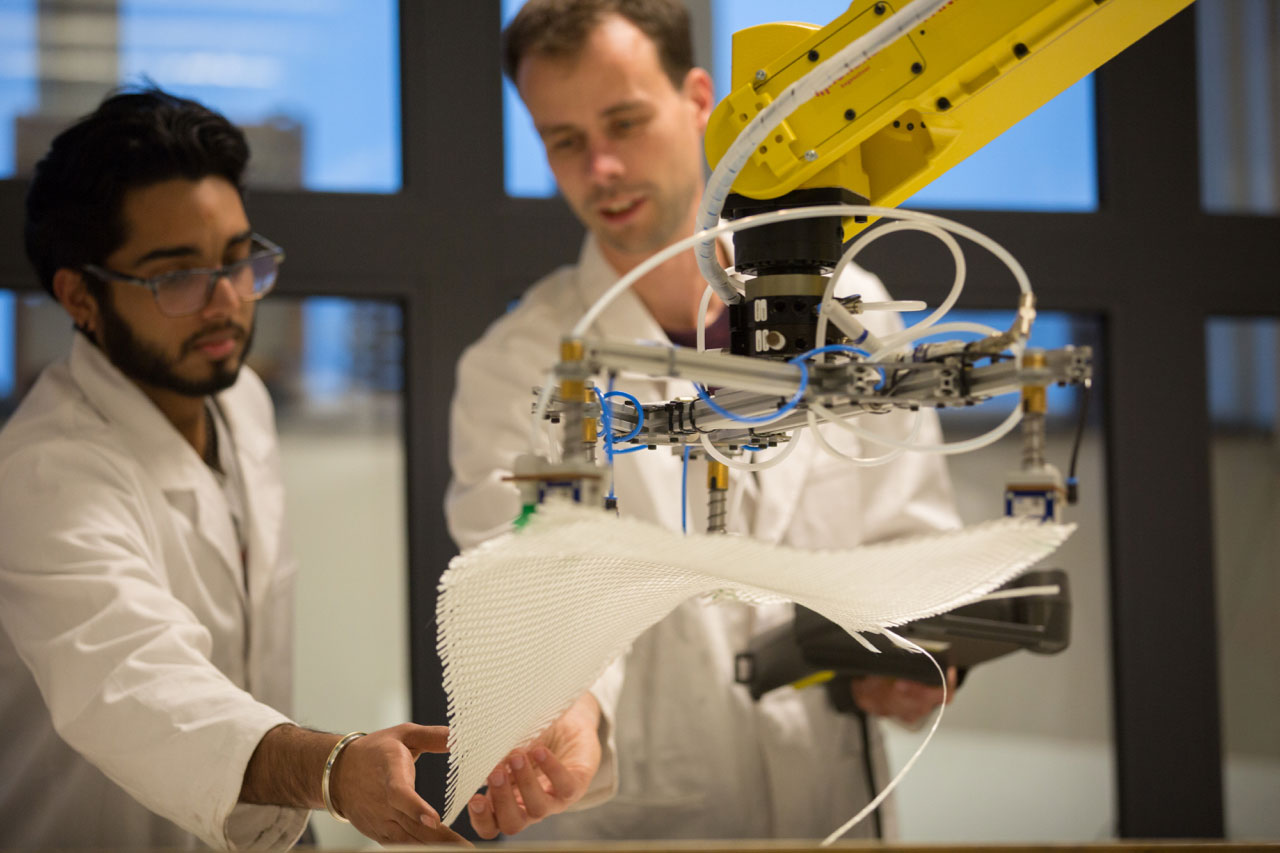

In 2016 this resulted in the delivery of the Robocompo project where Inholland initiated a consortium as part of a RAAK MKB project. Two years of research resulted in several demonstrators capable of handling subroutines for automated composites producion. The main focus was to create solutions for automation of the vacuum infusion process.

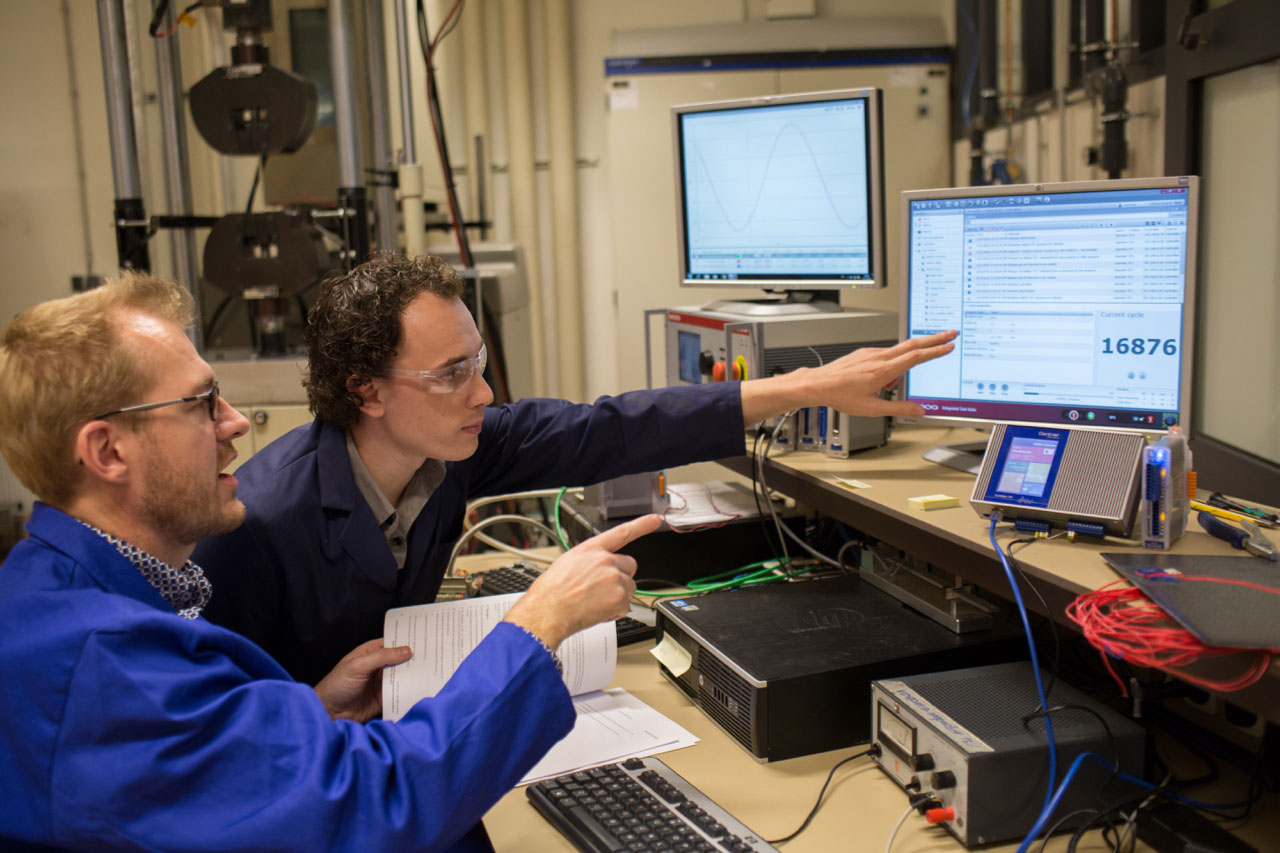

Another dimension of automation for the composites industry is the automation of an existing dynamic test bench at Inholland Composites. This hydraulic test bench is typically used for the validation of material properties and component samples for the Automotive- and Aerospace industry. A modernisation strategy was initiated and in september 2016 a graduation student started with the first step of transforming the test system in to a Smart Bench. Moog BV and Gantner Instruments started collaborating with Inholland Composites in their desire to experiment with new ideas in this field. They use this as an opportunity to validate new integrated test solutions and therefore allow students to gain expertise in automation of structural test systems.