Successful design reviews for Lightweight Structures project teams Aeronautical Engineering

09 Apr 2018

On April 6 a group of 30 people participated in several design reviews at Inholland Composites in Delft. 3rd year students from Aeronautical Engineering Inholland Delft presented their designs to representatives from Carbonracing, Fokker/GKN Aerostructures, Atmos and DARE as part of their Lightweight Structures minor which is one of the specialisation options within the study programme. The project teams have until end of June to deliver their results to these companies which include a manufactured and tested design. The project activities are executed at Inholland Composites in Delft where the students gather every week to work together and use the laboratory equipment to design, build and test a concept for their customers.

Carbonracing:

Carbonracing is a startup company in Delft owned by a former Fokker engineer with an ambition to develop a new line of carbon fibre wheels. The aeronautical engineering students were asked to perform research in the best vacuum infusion strategy, which is one of the manufacturing options under consideration by Carbonracing. With the research performed so far, the project team has frozen the design such they can start preparing for manufacturing in the next few weeks. This will include cores from wax.

Fokker Aerostructures:

Acquired by GKN in 2015, Fokker Aerostructures has a long history in the aviation industry. They provides empennages, wing structures, fuselages and components for major platforms ranging from helicopters to business jets and from advanced fighter aircraft to the largest passenger planes in the world. In this industry a lot of research is still being done in establishing the proper design factors for open holes for carbon fibre laminates. Although this seems straight forward, a lot of data is still unknown which provide Fokker with the idea to ask Inholland to do open-hole tension tests. The team rounded up the design and is planning on producing 80 samples which will be tested with tensile loads up to 220kN.

Atmos UAV:

Atmos UAV is a Delft based company specialised in the design and production of high-end aerial surveying and data collection systems. It’s flagship drone model, Marlyn, has a worldwide unique design that combines the flexibility of helicopters with the high performance of conventional fixed-wing aircraft. With their patented technology, Atmos is targeting the global mapping industry, from construction and mining to agriculture and environmental applications for governmental, academic and SME institutions. To achieve extended flight times, the Inholland project team has been asked to find ways to reduce weight in the tail-section and improve the production lead times. The chosen monocoque/sandwich design is now being prepared for production at Inholland Composites in the next few weeks.

DARE:

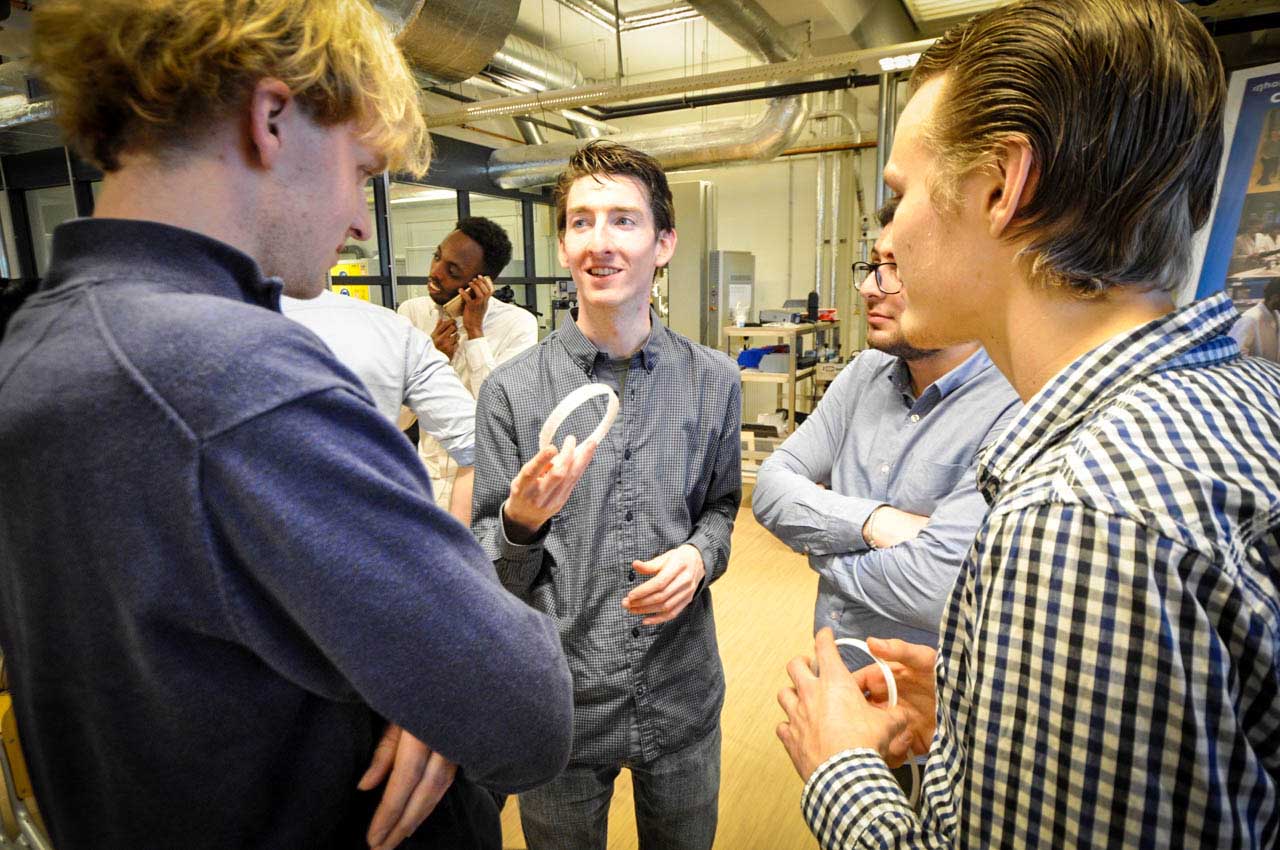

Delt Aerospace Rocket Engineering (DARE) is one of Europe’s most successful university student rocket societies. Dare performs spaceflight research and development on all fronts- from liquids, solid and hybrid engines to electronics and actively stabilised rockets and is looking for a new design for the connecting collar of the STRATOS rocket. The Inholland project team is performing research in establishing the most suitable design for the connecting collar that allows for a more sufficient manufacturing process that reduces the production time, cost and material waste. Their design is aiming for a mix of short and chopped fibres in the reinforced collar. Production and testing will start soon.

The 4 project teams performed well during their presentations of the designs and are now getting ready to start manufacturing and testing their designs. It was the first time to perform these design reviews in an open format where everyone was welcome to join. This provided the benefit of maximising the group learning. Afterwards all project teams members were invited to stay for a drink and enjoy the first glimpses of the sun outside the autoclave area. In case you want to know more about this topic, contact Inholland Composites.

Inholland Composites is a ‘knowledge factory’ at Inholland and part of the Research & Innovation Centre in Technology, Design & Computer Science, where lecturer-researchers, professors and students work together on a research programme to solve social issues as well as contribute to a sustainable, healthy and creative society.

Great design reviews today with the Lightweight Structures project teams from Aeronautical Engineering @InhDelft Thanks everyone, good luck with building and testing your designs for @DARE_TUDelft @ATMOSUAV @Fokker #carbonracing pic.twitter.com/ZElbXLivxJ

— Inholland Composites (@Inh_composites) 6 april 2018

Leave a Reply